Contact Us

|

Home

/

Product video

|

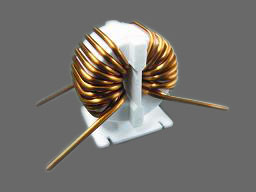

About Automatic Winding Machine

It not only can 24 hours full time working, but also can avoid many problems which handwork may meet.

Manual operation | Automatic production | |

Winding Tension

| Winding tension has deviation

| Invariable Winding Tension |

Winding tightness

| Due to one core is not pressed on the other when winding, wire can’t be tightly attached to the core

| Winding after one core is pressed on the other, wire can be tightly attached to the core |

Product consistency | Different workers, different products. | All products are wound same way. |

Winding Speed | Different operators have different winding speed. And the speed is slow. | There’s no difference of winding speed and it’s relatively quick. |

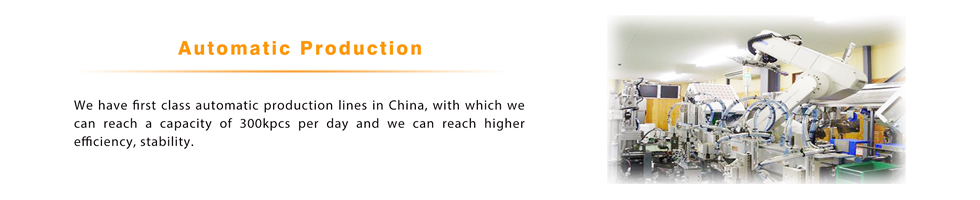

Process Overview

As shown below, it is carried out full-automatically from winding to test.

Please refer to the following pictures and videos about the producing state of automatic winding machine.

Video - TOROIDAL INDUCTOR AUTMATIC PRODUCTION

hint

Please fill in the fields correctly

Subscription succeeded